INSPEX

Remote magnetic pipe inspection

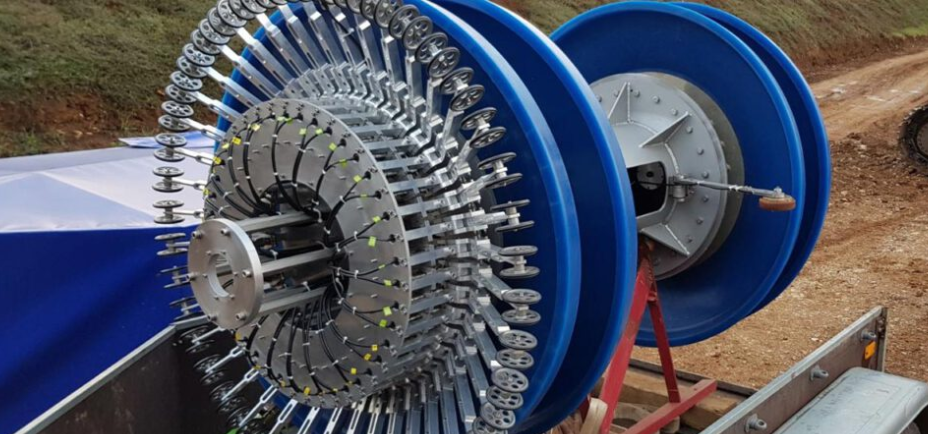

Inspex technology

Remote Magnetic Inspection Technology based at Villari effect

New generation magnetic sensors

Advanced software for signal processing

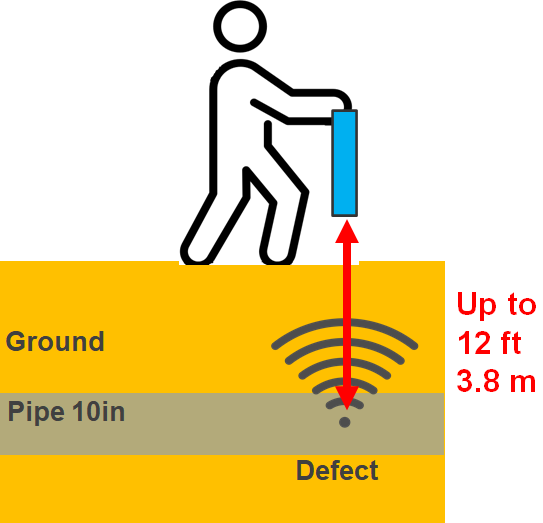

The distance from tool to buried pipe, up to 15 diameters of pipe

Investigation depth from 12 feet and higher

New generation magnetic sensors

Advanced software for signal processing

The distance from tool to buried pipe, up to 15 diameters of pipe

Investigation depth from 12 feet and higher

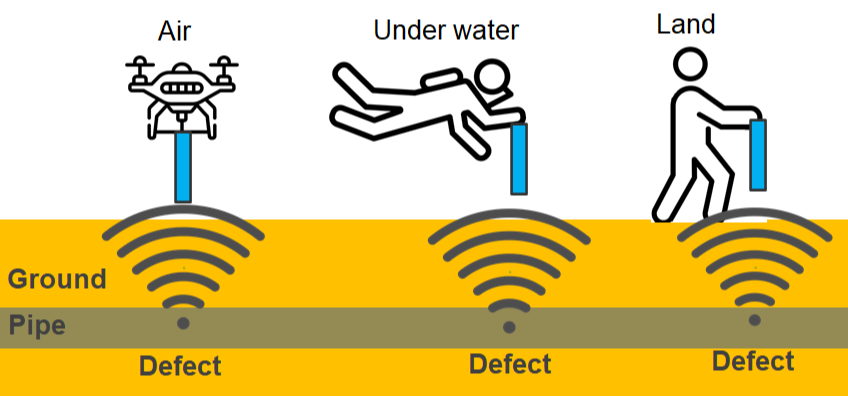

We can carry out inspection anywhere

Comparison Inspex vs Conventional

Inspex• Low cost

Inspex• Low cost

• High speed of work

• Inspection of non-piggable pipeline sections

• Inspection without stopping the pipeline flow Conventional• High cost of work

Conventional• High cost of work

• Need for preparatory work

• Stopping product transportation for the duration of inspection

• Significant limitations on applicability

•Risk of smart pig stacking

Case study and Client feedback

Report example of 48" gas pipeline

19 - points of inspection

12 points - critical

2 points - supercritical

Verde Generation company feedback:

We were impressed with INSPEX technology and our company managed to save 250 000$ for infrastructure construction cost

19 - points of inspection

12 points - critical

2 points - supercritical

Verde Generation company feedback:

We were impressed with INSPEX technology and our company managed to save 250 000$ for infrastructure construction cost

ADVANTAGES

• Remote - distance from pipe to tool up to 15 pipe diameters

• Not require stopping or reducing the volume of oil or gas transportation

• Detecting anomalies in real time

• High performance – up to 30 km per day

• Could work at non-piggable pipelines

• Automatic pipeline tracing

• Ability to operate in high electromagnetic environments

LIMITATIONS

• Requires a pressure of at least 5 bar (75 psi)

• Applicable only on steel pipelines

• Remote - distance from pipe to tool up to 15 pipe diameters

• Not require stopping or reducing the volume of oil or gas transportation

• Detecting anomalies in real time

• High performance – up to 30 km per day

• Could work at non-piggable pipelines

• Automatic pipeline tracing

• Ability to operate in high electromagnetic environments

LIMITATIONS

• Requires a pressure of at least 5 bar (75 psi)

• Applicable only on steel pipelines

Detectable anomalies

1.Stress-deformed states

2.Corrosion and fatigue stresses

3.Defects related to metal loss and metal strength violations

4.Changing the pipeline geometry

5.Unauthorized tie-ins and repair sites

2.Corrosion and fatigue stresses

3.Defects related to metal loss and metal strength violations

4.Changing the pipeline geometry

5.Unauthorized tie-ins and repair sites