170+ casing welding jobs since 2021

4 1/2" casing welding at rig site

9 5/8" casing welding at rig site

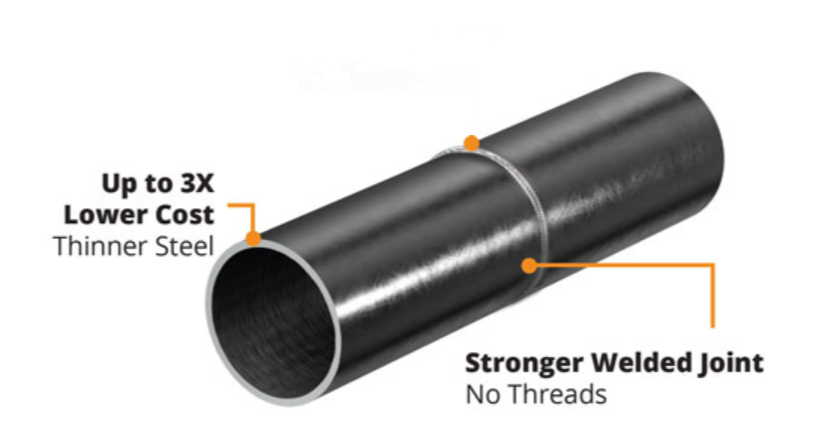

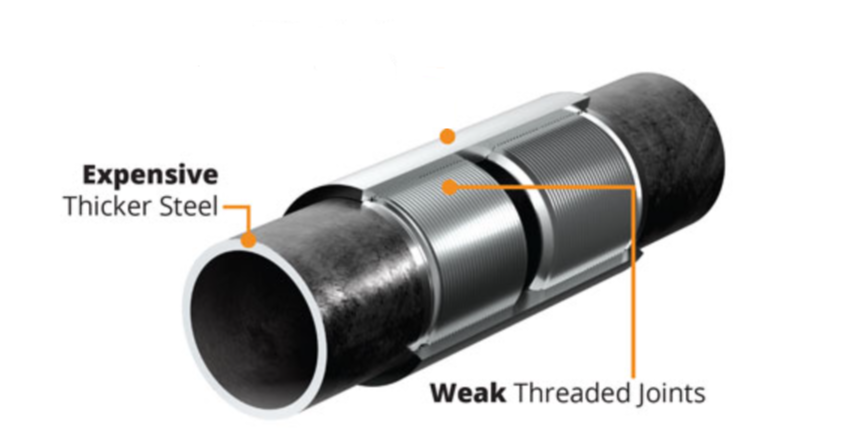

Welded vs threaded casing

WELDEDLower well construction costs - slim hole opportunities

WELDEDLower well construction costs - slim hole opportunities

High maximum torque available for casing rotation

Enhanced cement jobs with casing rotation

High strength and better casing integrity THREADEDHigher well construction cost

THREADEDHigher well construction cost

Larger well diameter & volume drilling fluid & cement

Less torque for casing rotation

Poor cement jobs without casing rotation

Weaker casing strengthless casing integrity

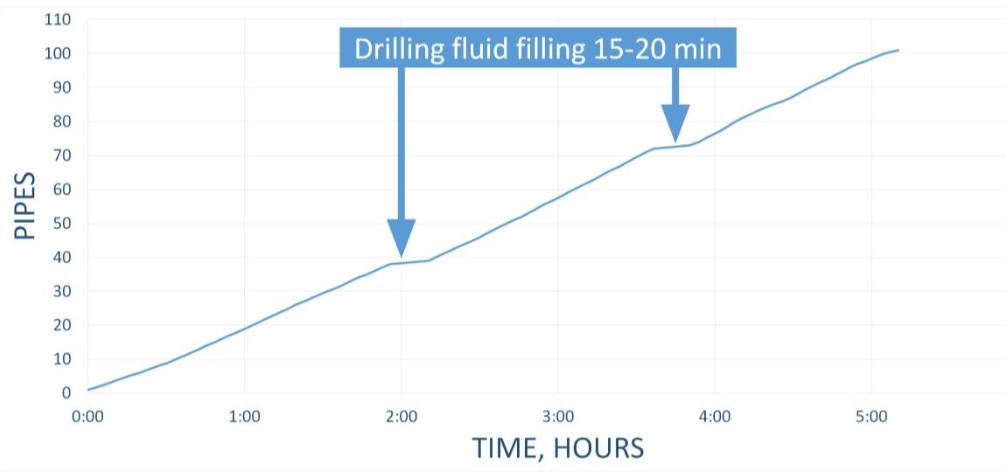

Field-Proven Run-In-Hole Speed:

5 hours to run 4½in casing to 3,000 ft depth

Frictionless RIH with coupling-free design

Frictionless RIH with coupling-free design

Laboratory tests

TORQUE TEST4½in casing

TORQUE TEST4½in casing

23.4 kNm Force

No weld damage TENSILE STRESS TESTNo weld damage

TENSILE STRESS TESTNo weld damage BENDING STRESS TESTNo cracks at weld joings

BENDING STRESS TESTNo cracks at weld joings

114x6.3mm (41/2") casing | Welded joint | Threaded joint |

Casing Type | low cost A 516-55 Steel | high cost N80 Steel |

Maximum Torque | 35 kNm / 25.8 ft-lbs | 13 kNm / 9600 ft-lbs |

Burst Pressure | 775 bar / 11200 psi | 623 bar / 9000 psi |

Tensile load capacity of casing string, kN | >1600 | 1360 |