Remote magnetic pipe inspection

Inspex technology

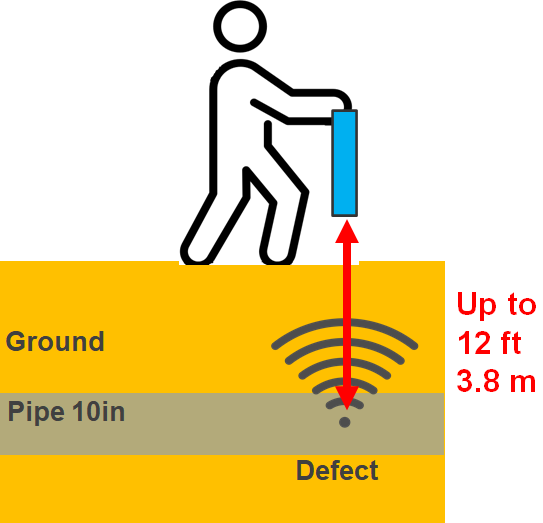

INSPEX leverages Remote Magnetic Inspection Technology grounded in the Villari Effect (magnetostriction), where mechanical stress alters a material’s magnetic properties.

This enables real-time anomaly detection in steel pipelines using advanced magnetic sensors and signal-processing software.

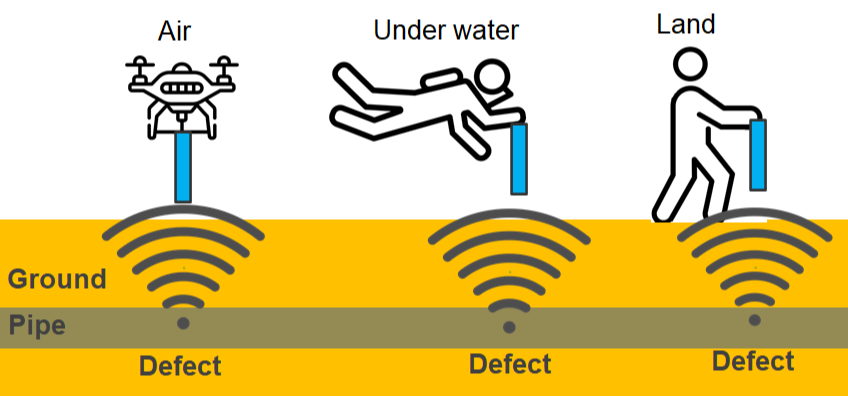

We can carry out inspection anywhere

Comparison

Inspex

Inspex• Low cost

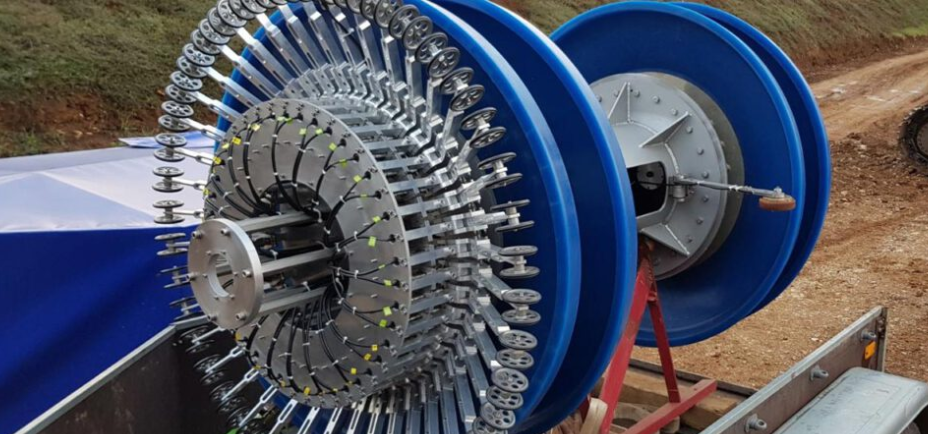

• No flow interruption

• No pigging required

• Rapid deploymen

• Broad applicability Conventional• High operational costs

Conventional• High operational costs

•Requires reduce product transport

• Risk of smart pig jamming

•Extensive prep work needed

•Limited to piggable pipelines

Advantages

Cost-effective: Reduces downtime and pigging infrastructure.

Real-time analysis: Immediate defect detection and reporting.

Automated tracing: Accurately maps pipeline routes.

Limitations

Material restriction: Only applicable to steel pipelines.

Pressure requirement: Minimum 5 bar (75 psi) internal pressure.